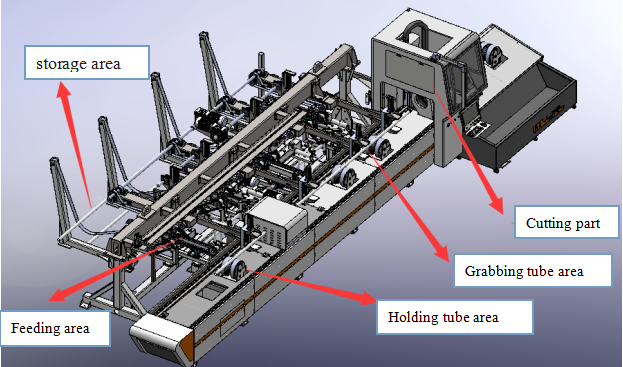

Komatsu tlm610 laser cutting system the tlm series of 5 axis laser cutting systems simplifies the processing of 3 dimensional workpieces to perform any number of cutting tasks.

5 axis laser tube cutting.

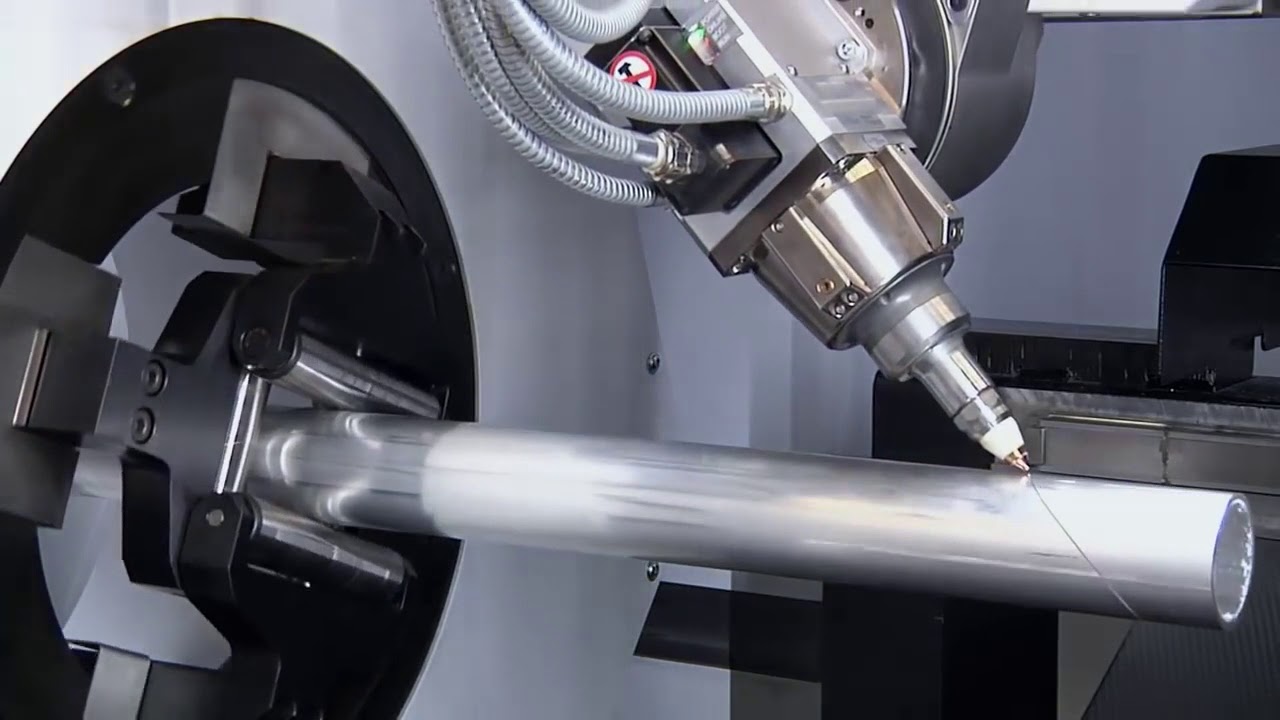

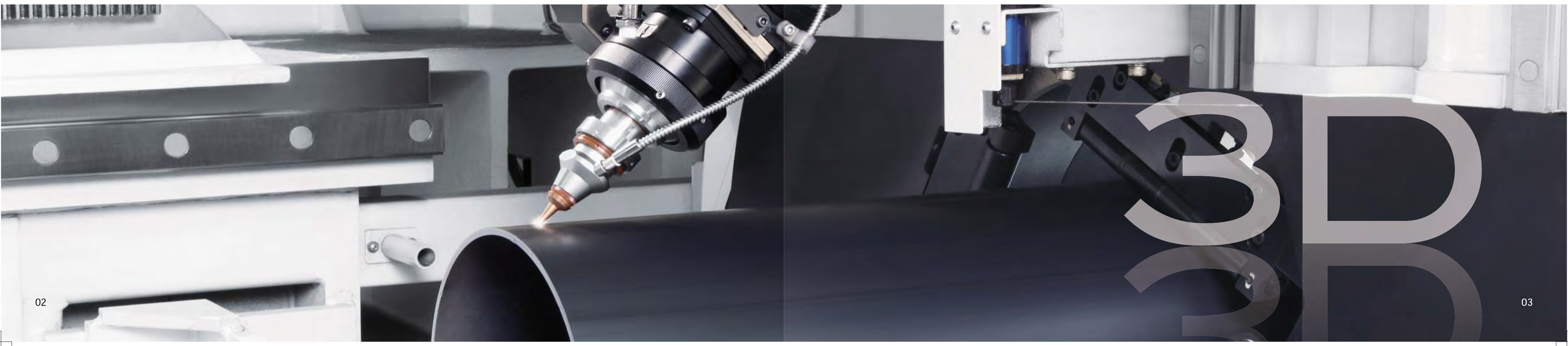

Tube laser head is rotating on a 360 degree radius above the laser nozzle like an owl s head so to speak.

Most industrial engineers have only begun to understand how this technology can change design and engineering.

5 axis laser cutting bassett s multiple open architecture 4000 watt 5 axis lasers allows for cutting and trimming of formed sheet metal parts formed tubes assemblies large tubes to 30 in diameter drawn parts prototypes and many configurations not previously able to be processed with traditional fabrication processes with extreme accuracy and repeatability.

Use the robot to eliminate manual repositioning with highflex and oneflex versions parts such as bent or hydroformed tubes may be cut in a single cycle.

The 5 axis fiber laser cutting system lt free is perfect to process any complex part.

Ultimately with all these axis operating simultaneously the tube laser can cut a huge array of shapes and sizes with cutting surfaces that are normal and angle cut to the surface of the metal.

You can see how quick this machine travels round the panel.

5 axis cutting also allows amf to cut items like angle channel and custom extrusion none of that is possible on a flat sheet laser.

Dedicated 5 axis tube laser cutting is on the frontier of fabrication.

The robot positions the part in space so that reworking on fixed templates is eliminated.

Run programs from g code or an ntc developed simplified coding process.

The exhaust systems prototyping step has also been drastically shortened.